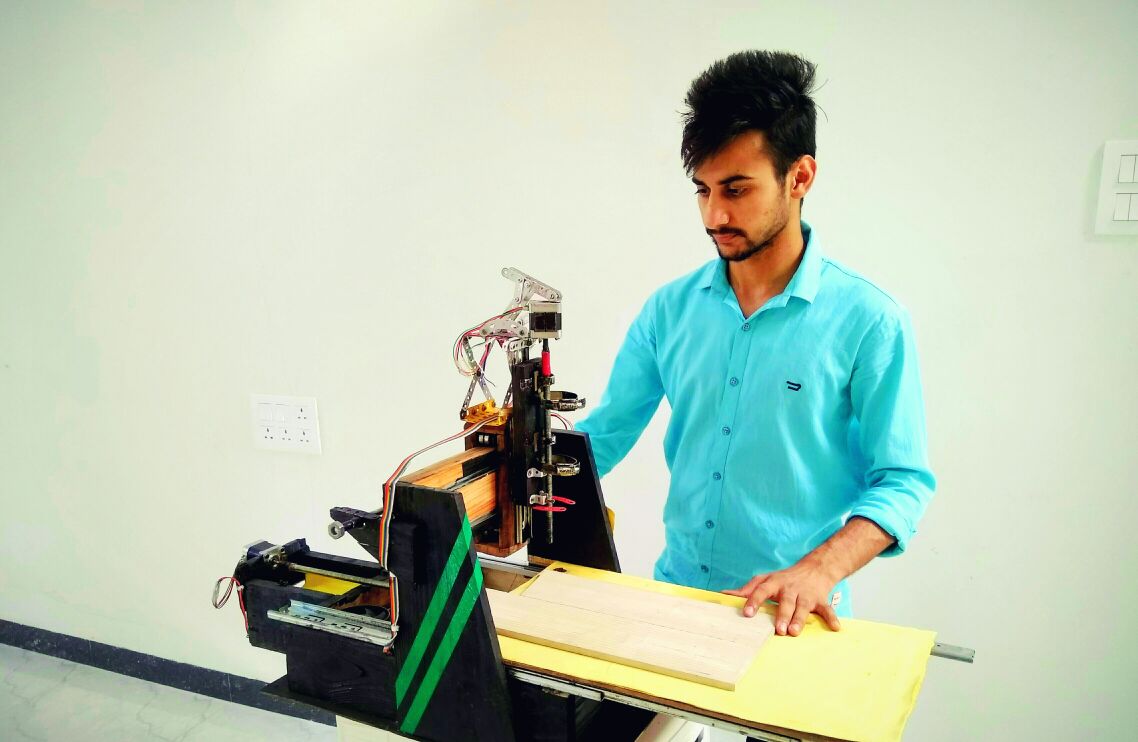

Nehul Patel, a 3rd Semester B.Tech Electronics and Communications student of Lovely Professional University recently developed a Computer Numerical Control machine, also known as CNC machine. He designed this machine entirely from scrap materials and with the cost of around INR 4000 which is much lesser to the market price of the same machine which is around 2-3 lakhs. The machine has a working area of 20×10 inches. It is a 3- Axis machine and has multiple features like drilling, sculpting, engraving and plotting.

“The idea to design this machine came from my brother who is a businessman. We deal in plywood and doors designing and engraving. So he wanted a CNC machine to make more creative doors by engraving different designs and patterns. So I inquired to him what the CNC machine is and started doing research on it. With the help of online resources and my brother’s guidance, I understood the working process of the CNC machine. As the original machine is quite costly, I started to look for ways to optimize the cost. I begin searching for the alternatives of the costly parts of the machine. After about a month, my 1st CNC machine which was built from scrap materials was ready with just a budget of 4000”.

As the intellects say, a true genius mind can’t stay at rest for long, so is the case with Nehul. After the completion of the 1st basic CNC machine, he decided to improvise it. After Research and Development (R&D) on various CNC machines, he decided to build a machine which should be more precise as well as more optimized in cost. Under the guidance of Dushyant Kumar Singh, the Head of Department and Raghav Gupta, Faculty of his department, he was successful in building an enhanced model of the CNC machine. After the modifications, the new machine can even do tasks like 3D printing with just a change of the main tool.

Nehul’s innovation is quite revolutionary as in today’s era there is no single machine which can perform both the functions of CNC machine and a 3D printer. The combination of both the models has not only reduced to the trouble of maintaining both machines but is also quite cost-effective. As this machine is very beneficial across various sectors like industrial, educational, medical purposes (dentist, surgeons), engineering (mechanical, architecture), etc., it is a proud moment for Lovely Professional University that one of its students has come up with such a concept.